Product Description

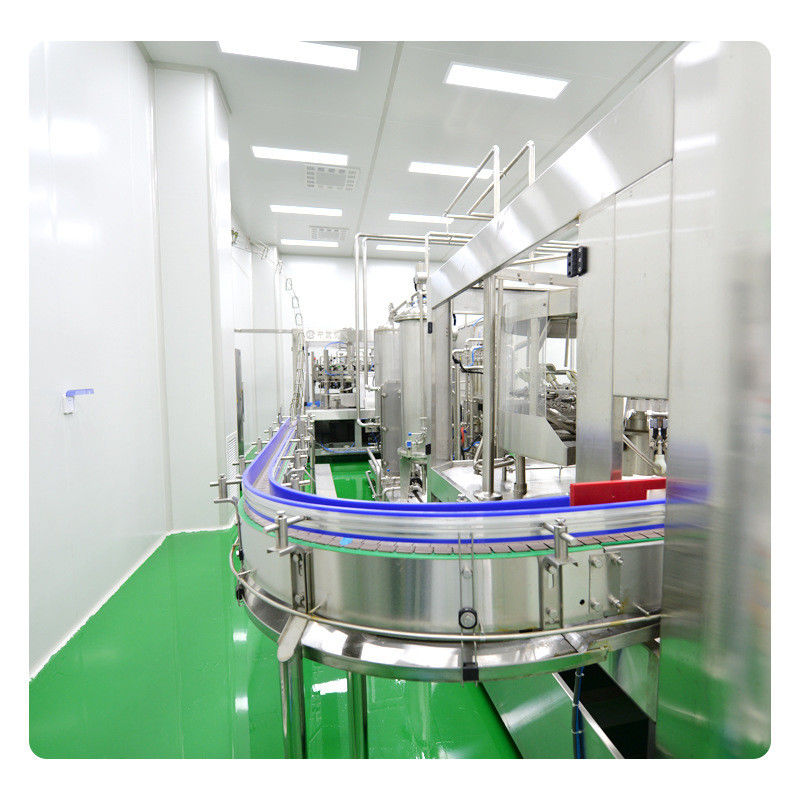

ISO 8 Monitoring HVAC GMP Clean Room In Pharmaceutical Industry

Pharmaceutical packaging GMP cleanroom

Environmental control requirements

(1) Provide the air purification level required for production. The number of air dust particles and live microorganisms in the purification process of the packaging workshop should be regularly detected and recorded. The static pressure difference between the packaging workshops with different grades should be kept within the specified values.

(2) The temperature and relative humidity shall be compatible with the requirements of the production process.

(3) The production area of penicillins, highly sensitizing and anti-tumor drugs should be provided with an independent air-conditioning system, and the exhaust gas should be purified.

(4) An effective dust-collecting device should be provided for the room where dust is generated to prevent cross-contamination of dust.

(5) For auxiliary production rooms such as warehousing, the ventilation facilities and temperature and humidity should be compatible with the production and packaging requirements of the drug.

Cleanliness zone and number of air changes:

(1)The clean room should strictly control the air cleanliness, as well as the ambient temperature, humidity, fresh air volume and pressure difference etc.

The air cleanliness of pharmaceutical production and packaging workshop is divided into 4 grades .

class 100 , 10,000 ,100,000 and 300,000.

To determine the number of air changes in the clean room, it is necessary to compare the various air volumes and take the maximum value.

In practice, class100 air exchanges is 300-400 times/h,

Class 10,000 air exchanges is 25-35 times/h,

Class 100,000 air exchanges is 15-20 times/h.

(2) The specific cleanliness class in the production and packaging environment of pharmaceuticals shall be in accordance with the national standard for purification.

(3) Determination of other environmental parameters of the purification engineering of the packaging workshop.

(4) Packaging workshop purification engineering temperature and humidity Clean room temperature and relative humidity should conform to the pharmaceutical production process.

Temperature

Class 100 and 10,000 20~23 ℃(summer)

100,000 and 300,000 24 ~26℃, and the general area is 26 ~27℃.

Class 100 and 10,000 are sterile rooms.

Relative humidity:

45%- 50% moisture-absorbing drugs (summer),

50% -55% solid preparations such as tablets,

55%- 5% water needles and oral liquids.

clean room pressure

The clean room pressure to maintain indoor cleanliness needs to maintain a positive indoor pressure.

The clean room for the production of dust, harmful substances, and production of penicillin-based strong allergenic drugs must prevent the inflow of external pollution and the outflow of internal air. Therefore, the room must maintain a positive pressure and maintain a relative negative pressure between adjacent rooms or areas.

The static pressure of different cleanliness rooms is greater than 5Pa, and the static pressure difference between clean room and outdoor atmosphere is greater than 10Pa.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!